Pressure Vessel Pipe Self Aligned Welding Rotator

Get Latest Price| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,your request |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,your request |

Model No.: GLHZ

Brand: Zhouxiang

Types Of: Welding Turning Roll

Old And New: New

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Building Material Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High Safety Level, Low Noise Level, Automatic, Easy To Operate, Multifunctional, Long Service Life, Energy Saving

Product Name: Hot Selling Self-Adjusting Roller Stand Self Alignment Welding Rotator

Model: GLHZ

Max Supporting Weight: 5000 kg

Wheel Working Linear Speed: 6-60 m/h

Input Voltage: 3P 220V-470V 50/60Hz/

Frame Center Distance: 940 mm

Speed Adjust Way: VFD Adjust

Wheel Material: Polyurethane(PU)/Metal+Rubber/Steel

Function: Tank Automatic Welding cutting rolling

Control: Remote Controller/Wireless Controller(optional)

| Selling Units | : | Set/Sets |

| Package Type | : | pipe welding rotator in naked,wooden case,steel frame,export standard packing |

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Self-aligned Welding Rotator

Self-aligned Welding Rotator Introduction:

The self-aligned turning roll is designed to aid the welding of tanks. By using independent drive and idler units, tanks of varying lengths can be placed on the turning rolls supported on the turning rolls wheels. The power welding rotator and the passive welding rotator can be moved on the track, and the distance between them can be adjusted to weld cylinders of different lengths. The wheels of self aligned welding rotator can be opened on the base frame to accommodate different vessel diameters. Our heavy duty, built to last self aligned welding rotators are designed and manufactured to tolerate the hardest, hard-wearing and unrelenting workload environments.

Self-aligned Welding Rotator Technical Parameters

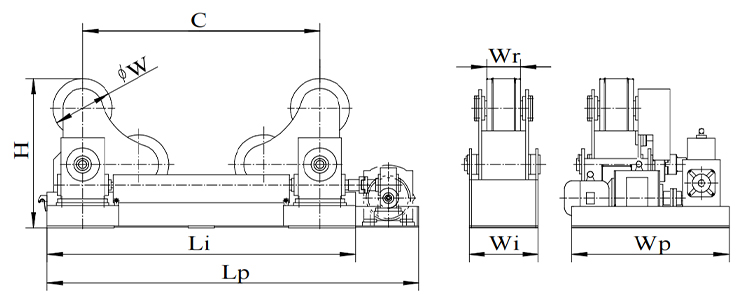

| Model | Load & Rotation Capacity (Ton) | Tanks Diameter Range (mm) | Rotation Speed (mm/min) | Driven Motor Power (Kw) | Frame Center Distance | Wheels Diameter & Width | Roll Dimensions (mm) | |

| C (mm) | ΦW * Wr (mm) | Lp * Wp * H | Li * Wi * H | |||||

| GLHZ-5 | 5 | 250-2300 | 100-1000 Speed adjusted by VFD | 0.75 | 940 | 250*140 | 1560*695*692 | 1240*380*692 |

| GLHZ-10 | 10 | 320-2800 | 1.5 | 1100 | 300*150 | 1800*705*805 | 1440*400*805 | |

| GLHZ-20 | 20 | 500-3500 | 2.2 | 1400 | 350*180 | 2180*910*895 | 1780*480*895 | |

| GLHZ-40 | 40 | 600-4200 | 3 | 1600 | 400*200 | 2448*1000*1018 | 2040*530*1018 | |

| GLHZ-60 | 60 | 750-4800 | 4 | 1800 | 450*220 | 2770*1100*1095 | 2340*585*1095 | |

| GLHZ-80 | 80 | 850-5000 | 4 | 2000 | 500*240 | 2975*1165*1198 | 2540*620*1198 | |

| GLHZ-100 | 100 | 1000-5500 | 5.5 | 2200 | 500*280 | 3380*1405*1320 | 2800*730*1320 | |

| GLHZ-150 | 150 | 1100-6000 | 7.5 | 2500 | 600*280 | 3870*1600*1550 | 3240*800*1550 | |

| GLHZ-250 | 250 | 1200-7000 | 2*5.5 | 2800 | 700*300 | 4468*1620*1785 | 3620*860*1785 | |

| GLHZ-500 | 500 | 1800-8000 | 2*7.5 | 3500 | 850*350 | 5562*1784*2062 | 4420*950*2062 | |

| Model | Load & Rotation Capacity (IBS) | Tanks Diameter Range (in) | Rotation Speed (mm/min) | Driven Motor Power (HP) | Frame Center Distance | Wheels Diameter & Width | Roll Dimensions (mm) | |

| C (mm) | ΦW * Wr (mm) | Lp * Wp * H | Li * Wi * H | |||||

| GLHZ-5 | 11,000 | 9 27/32--90 35/64 | 100-1000 Speed adjusted by VFD | 1.0 | 940 | 250*140 | 1560*695*692 | 1240*380*692 |

| GLHZ-10 | 22,000 | 12 19/32--110 15/64 | 2.0 | 1100 | 300*150 | 1800*705*805 | 1440*400*805 | |

| GLHZ-20 | 44,000 | 19 11/16--137 51/64 | 3.0 | 1400 | 350*180 | 2180*910*895 | 1780*480*895 | |

| GLHZ-40 | 88,000 | 23 5/8--165 23/64 | 4.0 | 1600 | 400*200 | 2448*1000*1018 | 2040*530*1018 | |

| GLHZ-60 | 132,000 | 29 1/2--188 31/32 | 5.4 | 1800 | 450*220 | 2770*1100*1095 | 2340*585*1095 | |

| GLHZ-80 | 176,000 | 33 15/32--196 27/32 | 5.4 | 2000 | 500*240 | 2975*1165*1198 | 2540*620*1198 | |

| GLHZ-100 | 220,000 | 39 3/8--216 17/32 | 7.4 | 2200 | 500*280 | 3380*1405*1320 | 2800*730*1320 | |

| GLHZ-150 | 330,000 | 43 5/16--236 7/32 | 10.0 | 2500 | 600*280 | 3870*1600*1550 | 3240*800*1550 | |

| GLHZ-250 | 550,000 | 47 1/4 --275 19/32 | 15.0 | 2800 | 700*300 | 4468*1620*1785 | 3620*860*1785 | |

| GLHZ-500 | 1,100,000 | 59 1/16--314 31/32 | | |||||

Self-aligned Welding Rotator Details:

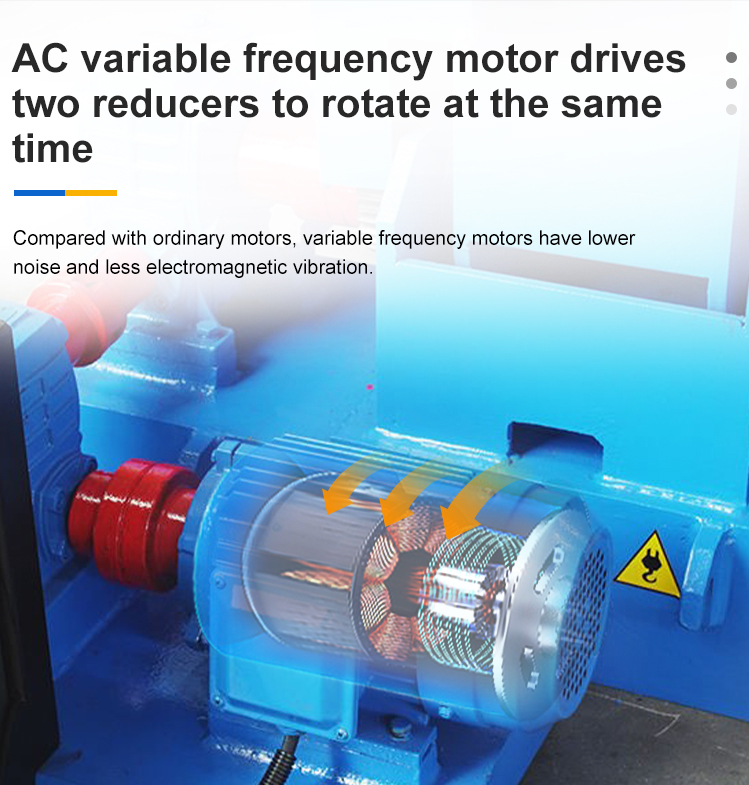

1:The self-aligned welding rotator is driven by one AC variable frequency motor to drive two gear reducers to rotate at the same time. Compared with ordinary motors, variable frequency motor has lower noise and smaller electromagnetic vibration.

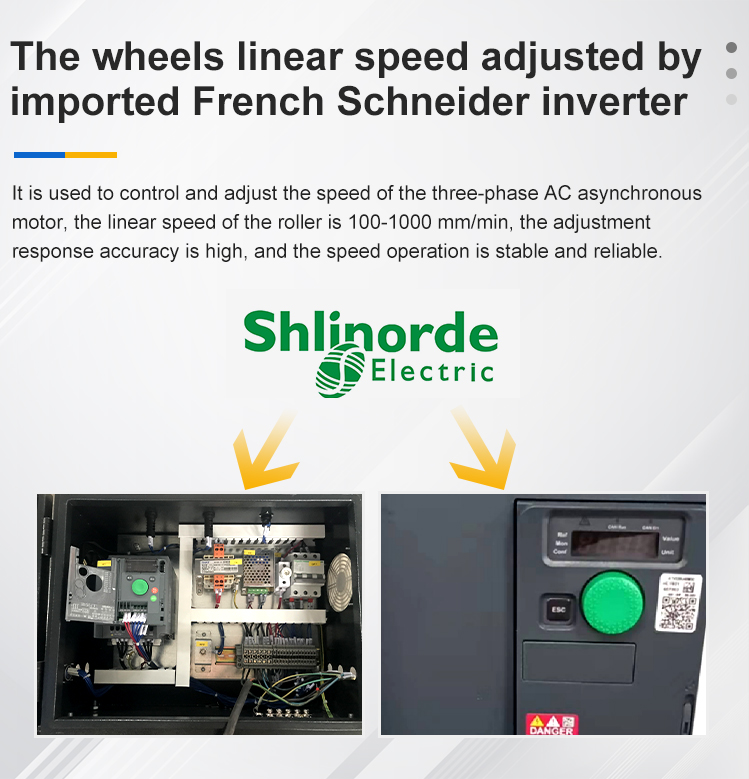

2:Schneider AC variable frequency governor is mainly used to control and adjust the speed of three-phase AC asynchronous motors, with stable performance, rich combination functions, good dynamic characteristics, super overload capacity and unparalleled flexibility. The linear speed of the roller is 100-1000 mm/min, the adjustment response accuracy is high, and the speed operation is stable and reliable.

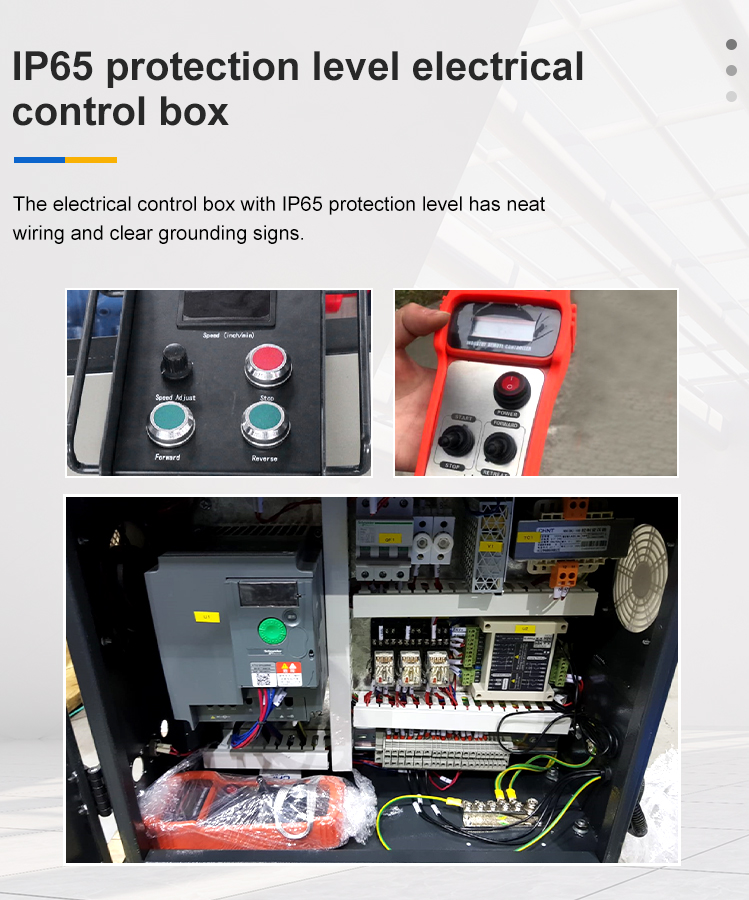

3: IP65 ingress protection electric cabinet has the protection function for field use. The wiring is neat and the grounding signs are clear.The operation panel has the functions of forward、reverse and stop. The speed is adjusted by the rotary button and displayed on the display screen.

What is “Automatic Welding Center”?

Automatic welding center refers to a key welding process in similar welding components as the core, and the components required to complete the welding process are arranged and combined according to the typical process procedures of the welding process, forming the completion of the welding process. workplace. Welding center is also called welding workstation.

The welding center consists of the following parts:

1. Welding power source: welding machine, machine head, wire feeder;

2. Welding machinery and equipment: such as workpiece roller frame, welding positioner, welding manipulator;

3. Welding auxiliary machinery: such as flux pads, flux conveying and recycling devices;

4. Workpiece transmission device: including feeding, conveying and unloading mechanisms;

5. Automatic welding seam tracking and automatic adjustment device for welding wire dry elongation;

6. Integrated electrical control system.

Why choose us--- China Zhouxiang Complete Set of Welding Equipment Co.,Ltd ?

As the largest H-beam manufacturing equipment manufacturer in China, we have strong design and manufacturing capabilities, with an annual production capacity of US$40 million.

How to produce qualified H-beam? It is an important category of our continuous research for 30 years. Our main products are: CNC Control Flame/plasma cutting machine、H beam Assembling machine、H Beam Welding Machine、H beam straightening machine、H beam shot blasting machine、H beam assembly-welding-straightening multi-functions machine、H beam Horizontal Productions Line、automation welding machine etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.