H-beam Hydraulic Straightening Machine

Get Latest Price| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Nantong |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Nantong |

Model No.: YJZ-60B, YJZ-60C, YJZ-60D, YJZ-80B

Brand: Zhouxiang

Place Of Origin: China

Types Of: Straightener &Amp; Cutter

Old And New: New

Use: H Beam Flange

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Pump, Motor, Gearbox

Warranty Period: 1 Year

Core Selling Point: High Productivity

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Building Material Shops, Machinery Repair Shops, Construction Works, Manufacturing Plant

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

H Beam Web Plate Height: ≥350 mm

H Beam Flange Plate Width: 180-800 mm

H Beam Flange Plate Thickness: 12-60 mm

H Beam Web Plate Thickness: 10-50 mm

Flange & Web Plate Material: Q345

H Beam Straightening Speed: 6.15 m/min

Main Driving Motor Power: 22 KW

Hydraulic Station Motor Power: 15 KW

Hydraulic Station Working Pressure: 25 Mpa

Hydraulic Station Max. Pressure: 31.5 Mpa

| Selling Units | : | Set/Sets |

| Package Type | : | Seaworthy packing |

| Picture Example | : |

|

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

H-beam Hydraulic Straightening Machine

H-beam Hydraulic Straightening Machine Structure principle:

This machine is used for straightening the deformation of H beam flange plate.

The straightening principle : two upper straightening roller press two side of flange plate ,one bottom roller support the center of flange , through the pushing of oil cylinder then up-press to the center of flange that reach to straightening the deformation of flange plate.

It is composed of machine frame , upper straightening roller , web plate clamp device , assistant support roller , lift oil cylinder , bottom straight roller , main transmission part ,input/output elevating roller, hydraulic system and electrical control system .

The machine frame is the carrier of all installation parts . It adopt thick steel plate whole welding , which have good structure rigidity and beautiful shape .

The two upper straighten roller install on top side of machine frame , it adopt shaft box structure , so it have big loading capacity . There have hydraulic cylinder in shaft box , it can adjust the distance of two upper straighten roller .The upper straighten roller is composed of straighten roller , straighten shaft , shaft box and bearing. Upper roller material is 35CrMo,it is treat by quench and grinding so that have good abrasive resistance .

Web plate clamp device adopt manual positioning , the other side adopt hydraulic oil cylinder push holding , adjusting the clamp position according to web thickness ,making the web plate in the center of bottom straightening roller . There have scroll bear in web clamp wheel that keep moving when clamping , which make sure the continuous working .

Assistant support roller is a transitions when beam from roller conveyor to straightening roller. When working on the bottom straightening roller , the beam will leave away the assistant support roller.

Lift oil cylinder install under the machine frame, there have bottom straighten roller on its top. It have big cylinder diameter, so it can make big lifting force that can support the weight of the beam.

Bottom straighten roller is composed of bottom straighten roller, bearing, bearing base, joint bottom plate and guide base .Bottom roller adopt forging structure , material is 40Cr,and process by quenching and grinding . So it has good abrasive resistance and anti-bending rigidity. The bearing base is on the joint bottom plate, the bottom is connecting with piston rod of lift oil cylinder. The guide base is install on the machine frame and connect with bearing base. When guide the bottom straighten roller , it also can increase whole rigidity .

Main transmission part is composed of universal jointer, gear reducer, cycloid gearbox and large power motor .When bottom straighten roller making whole elevating action , it must be adopt joint of universal jointer and reducer .

Roller conveyor adopt hydraulic elevating roller conveyor, it also can support the beam after bottom roller lift it .

Hydraulic system is composed of hydraulic station and pipeline system. It can supply the power for lift oil cylinder , web clamp oil cylinder , shaft box moving oil cylinder and elevating roller conveyor oil cylinder .

Electrical control system is composed of electrical control box and control cable, it is not only control the forward/reverse turning of main transmission motor , but also the electromagnetic valve of hydraulic station. Through hydraulic station to control the elevating of lifting oil cylinder , expansion of web plate clamp oil cylinder , forward /backward of shaft box moving oil cylinder , forward /backward of elevating roller conveyor oil cylinder .

H-beam Hydraulic Straightening Machine Technical parameters:

| Model | YJZ-60B | YJZ-60C | YJZ-60D | YJZ-80B |

| Flange width | 180-800mm | 200-1000mm | 200-800mm | 200-1000mm |

| Flange thickness | ≤60mm | ≤60mm | ≤40mm | ≤80mm |

| Web height | ≥350mm | ≥350mm | ≥160mm | ≥350mm |

| Workpiece material | Q345 | Q345 | Q345 | Q345 |

| Straightening speed | 6.15m/min | 6.15m/min | 9.8m/min | 6.56m/min |

| Total power | 37KW | 27.5KW | 20.5KW | 28KW |

| Hydraulic station pressure | 25Mpa | 25Mpa | 25Mpa | 20Mpa |

H-beam Hydraulic Straightening Machine Goods Supply Range:

a. Straightening machine: frame, motor reducer, universal jointer

b. Elevating roller: input and output roller conveyors

c. Hydraulic system: Hydraulic station, hydraulic cylinder and high press soft pipe .

d. Electrical control system: Electrical control box, control cable.

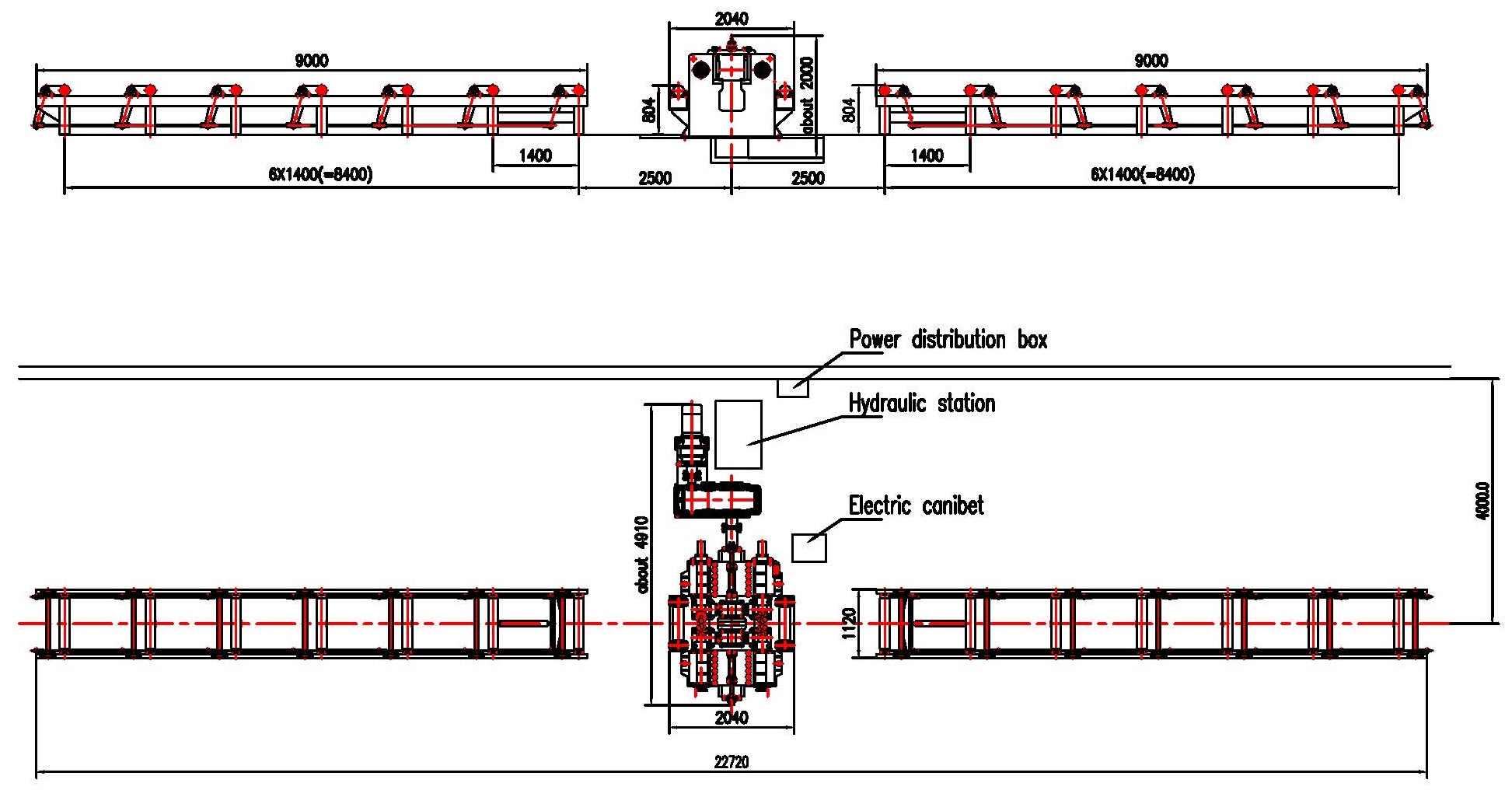

H-beam Hydraulic Straightening Machine Layout drawing:

H-beam Hydraulic Straightening Machine has independent control box:

H-beam Hydraulic Straightening Machine using hydraulic station to process:

Why choose us--- China Zhouxiang Complete Set of Welding Equipment Co.,Ltd ?

As the largest H-beam manufacturing equipment manufacturer in China, we have strong design and manufacturing capabilities, with an annual production capacity of US$40 million.

How to produce qualified H-beam? It is an important category of our continuous research for 30 years. Our main products are: CNC Control Flame/plasma cutting machine、H beam Assembling machine、H Beam Welding Machine、H beam straightening machine、H beam shot blasting machine、H beam assembly-welding-straightening multi-functions machine、H beam Horizontal Productions Line、automation welding machine etc.

How to choose H beam flange plate straightening machine?

As a professional welded H section steel equipment manufacturer, we provide various models of H-beam flange plate straightening machine. We generally choose the straightening machine according to the thickness and material of the flange plate.

| Flange plate thickness | Model | Flange plate correction way |

| 20 mm(Q235) | JZJ600 | Mechanical |

| 40 mm(Q235) | JZJ800 | Mechanical |

| 40 mm(Q345) | YJZ-60D | Hydraulic |

| 60 mm(Q345) | YJZ-60B | Hydraulic |

| 60 mm(Q345) | YJZ-60C | Hydraulic |

| 80 mm(Q345) | YJZ-80B | Hydraulic |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.