Box Column End Face Smooth Finishing Machine

Get Latest Price| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Nantong |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Nantong |

Model No.: DX1520 End Face Milling Machine

Brand: Zhouxiang

Types Of: Universal

Number Of Axes: 4

Number Of Spindles: Single

Processing Capacity: Medium Duty

Spindle Taper: Other

Workbench Stroke (X) (mm): 1200

Workbench Stroke (Y) (mm): 1500

Worktable Stroke (Z) (mm): 1000

Positioning Accuracy (mm): ±0.03

Repeat Positioning Accuracy (mm): ±0.05

Status: New

Place Of Origin: China

CNC System: Gsk

Core Selling Point: High-Accuracy

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction Works

Marketing Type: Ordinary Product

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump, Gearbox

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Sliding Table Size: 1200×750 mm

Sliding Table Stroke: 1500 mm

Moving Speed: 54.8-548 mm/min

Quick Return Speed: 822 mm/min

Horizontal Driving Motor Power: 3KW/4KW

Vertical Driving Motor Power: 1.5KW

Milling Head: 1TX32

Diameter Of Milling Cutter: 200-320 mm

Vertical Forward Speed: 53-530 mm/min

Quick Elevating Speed: 530 mm/min

| Selling Units | : | Set/Sets |

| Package Type | : | Seaworthy packing |

| Picture Example | : |

|

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Box Column End Face Milling Machine

Box Column End Face Milling Machine Structure Introduction:

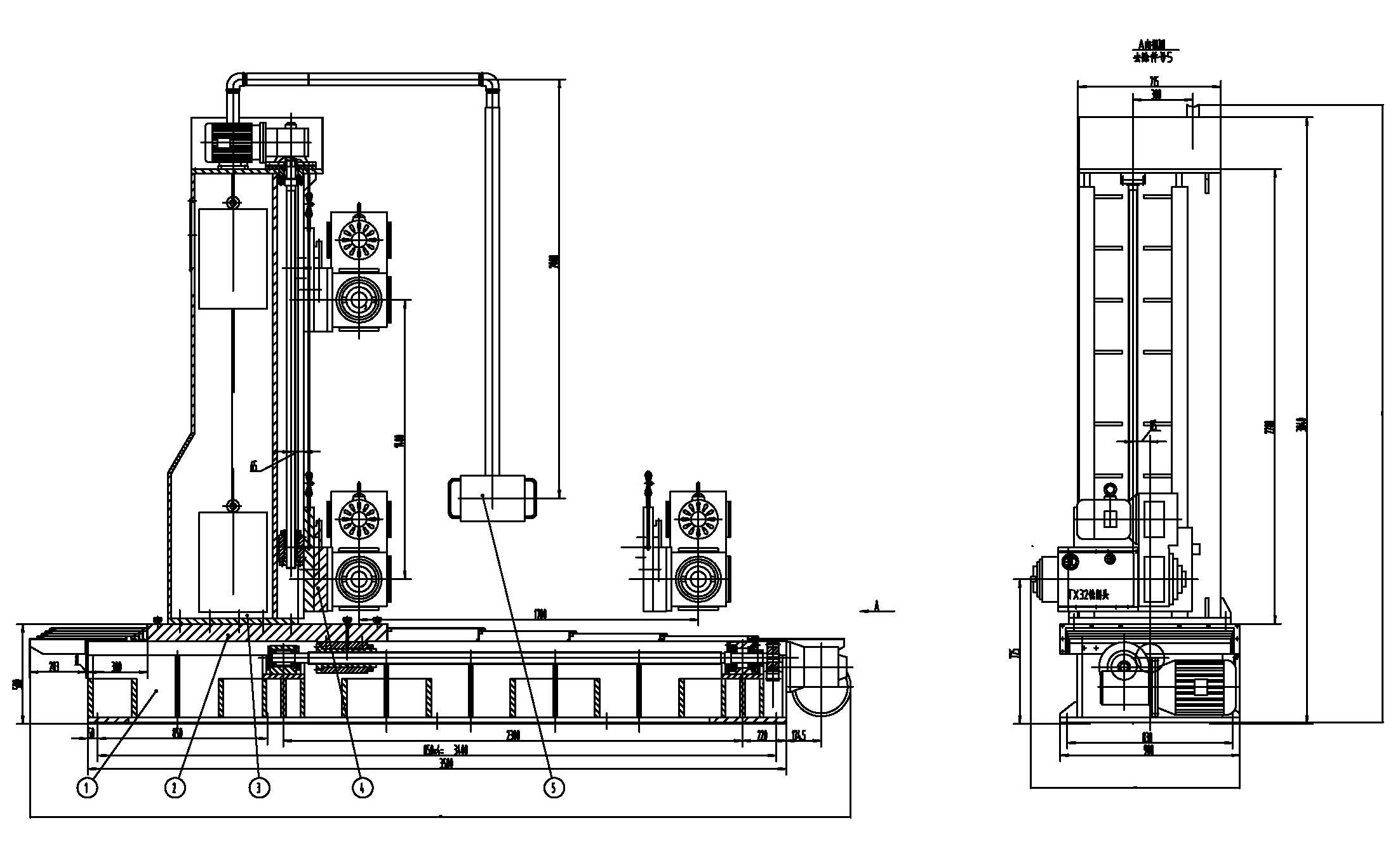

The H Beam and Box Column End Face Milling Machine is composed of horizontal driving, horizontal sliding table, vertical driving, vertical rotating sliding table and electrical control system

1. Horizontal driving

This is composed of table, horizontal feed motor, speed reducer, horizontal driving screw mandrel and screw nut. The table adopted welding structure and through annealing, and then through rough process and precision process. Its characteristics: high strength, little deformation, reasonable structure and good technology; one good load capacity rectangle track and one precision V-type track.

Horizontal driving mechanism is composed of feed box, trapezoidal feed screw driving and support frame; feed box adopted double speed motor, each used for horizontal feed and horizontal quick forward and backward during milling process; feed screw driving use drive and idle screw nut to guarantee the precision of horizontal driving; the two screw nuts fixed on the screw nut base frame at the same time, the screw nut base frame is connected with horizontal sliding table which drive the sliding table moving forward and backward along the track.

2. Horizontal sliding table

It is mainly composed of sliding table and track guard plate; the sliding table is casting; vertical mechanism such as column fixed on the sliding table.The track guard device adopted telescopic cover superposition has good leak tightness and long service life. There’s sight hole on the guard plate, so you can see the lubrication station and cleanliness and also can add oil to track; there’s cover plate on the sight hole, so you can cover the sight hole after finished.

3. Vertical driving

It is composed of column, driving motor, speed reducer, trapezoidal screw mandrel and screw nut; the column is welding structure member and through welding, stress relief, mechanical milling process; it has advantages of stability structure and high mechanical strength.

Vertical driving mechanism is composed of vertical driving motor, speed reducer, and screw mandrel and nut; screw driving used drive and idle screw nut to guarantee the driving precision.

4. Vertical rotating sliding table

It is composed of elevating carriage, rotating worm gear and standard milling head;the elevating carriage is made of gray cast-iron and match with the vertical track on the column, it has advantages of good wearable and shock proof; rotating worm gear is made of nodular cast iron, it has advantages of good wearable and high strength, and drive the milling head rotating 0-450 on the elevating carriage so that can enlarge the process range; the milling head has advantages of reasonable structure, reliable performance, large speed range( the speed of main shaft is 125-630rpm), good rigidity, low noise, high efficiency and convenient operation, and reduce users’ difficulty on choosing tools.

5. Electrical control system

It is composed of electrical control box and operation system.

Box Column End Face Milling Machine Technical parameter:

| Model | DX1215 | DX1220 | DX1520 | DX1525 | DX2025 | DX3030 |

| Milling motor power(Kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| sliding table dimension (mm) | 1200×750 | 1200×750 | 1500×750 | 1500×750 | 2000×750 | 3000×750 |

| sliding table stroke(mm) | 1500 | 2000 | 2000 | 2500 | 2500 | 3000 |

| Moving speed(mm/min) | 54.8~548 | 54.8~548 | 54.8~548 | 54.8~548 | 54.8~548 | 54.8~548 |

| Quick return speed(mm/min) | 822 | 822 | 822 | 822 | 822 | 822 |

| Horizontal driving motor power(Kw) | 4 | 4 | 4 | 4 | 4 | 4 |

| Vertical driving motor power(Kw) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Milling head | 1TX32 | 1TX32 | 1TX32 | 1TX32 | 1TX32 | 1TX32 |

| Milling cutter diameter(mm) | 200-320 | 200-320 | 200-320 | 200-320 | 200-320 | 200-320 |

| Quick elevating speed(mm/min) | 530 | 530 | 530 | 530 | 530 | 530 |

Box Column End Face Milling Machine Goods supply range:

a. Elevating column: 1TX32 milling head, elevating slide plate, elevating column, balance, elevating transmission mechanism.

b. Horizontal sliding table: working table, body, feeding power box, feeding screw mandrel.

c. Electrical control system: electrical control box, operation table and import AC converter.

d. Tool holding: drag bar, core shaft, Φ200 facing cutter

e. Box column or H beam holding device: hydraulic support frame, pump and oil pipe

Box Column End Face Milling Machine Drawing:

Box Column End Face Milling Machine Details:

GSK CNC Controller control the movement of the servo motor, which greatly improves the milling accuracy of BOX column.

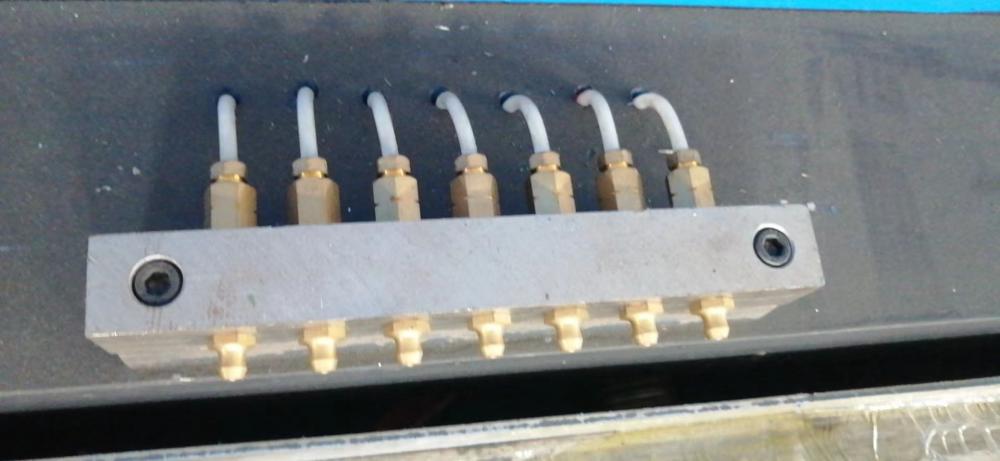

The centralized oil supply lubrication system keeps each lubrication point in a good lubrication state at all times.

Professional electrical control junction box and cable protection device to ensure that the wires are not worn and long life.

Why choose us--- China Zhouxiang Complete Set of Welding Equipment Co.,Ltd ?

As the largest H-beam manufacturing equipment manufacturer in China, we have strong design and manufacturing capabilities, with an annual production capacity of US$40 million.

How to produce qualified H-beam? It is an important category of our continuous research for 30 years. Our main products are: CNC Control Flame/plasma cutting machine、H Beam Assembling Machine、H Beam Welding Machine、H Beam Straightening Machine、H beam shot blasting machine、H beam assembly-welding-straightening multi-functions machine、H beam Horizontal Productions Line、automation welding machine etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.