Easy Operate Welding Cross Manipulator Column And Boom

Get Latest Price| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Model No.: LCH

Brand: Zhouxiang

Status: New

Type Of Machine: Welding Manipulator

Applicable Industry: Building Material Shops, Machinery Repair Shops, Construction Works

Out-of-warranty Service: Field Maintenance And Repair Service, Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Gearbox, Motor

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic, High Safety Level, Easy To Operate, Energy Saving, Long Service Life, Multifunctional

Boom Elevating Speed: 1 m/min

Boom Expansion Speed: 0.12-1.2 m/min

Column Rotating Angle: ±180°

Trolley Moving Speed: 1.5 m/min

Boom Payload At The Head: 200 kg

| Selling Units | : | Set/Sets |

| Package Type | : | wooden case |

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

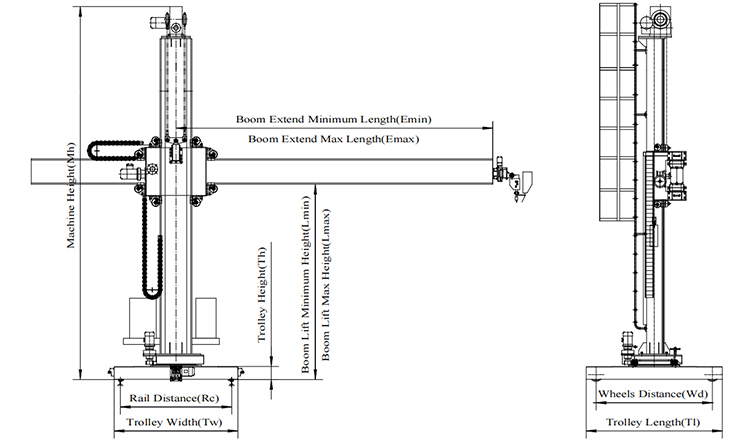

Column and Boom Structure principle:

LCH series welding manipulator is composed of column, welding arm, rotating mechanism, elevating mechanism, boom expansion mechanism, cross trimming, welding head, and electrical box,rotating and moving chassis. It can satisfy multi-direction welding requirements. The elevating of welding arm adopted the way of worm gear transmission and chain drive elevating, its speed changed by converter which has stable transmission and slow and stable speed change. Cross trimming mechanism is used to adjust the deviation between wire and work-piece.

We have built a portfolio of global leading welding machines, Manufactures a wide range of welding product portfolios including column and boom welding manipulators、welding rotator and welding positioner.Our column and booms welding manipulator consists of stationary, mobile, light duty, extra heavy duty and telescopic, etc. If your project demands are non-typical, our in-house capabilities and next-level engineering expertise enable us to develop special purpose welding manipulators for those more‘complex’ project needs. Our welding manipulator can be supplied full loaded with welding equipment (SAW, GTAW, GMAW and K-Tig) as a “turnkey” package or as the “steel work only”.

Column and Boom Technical parameters:

| Model | Boom In-Out Speed(m/min) | Boom Up-Down Speed(m/min) | Column Rotation Angle (±180°) | Trolley Speed (m/min) | Machine Height(mm) | Boom | Rail & Wheels Distance (M) | Trolley Size (mm) | |

| Horizontal Expansion (mm) | Vertical Expansion (mm) | ||||||||

| Mh | Emin--Emax | Lmin--Lmax | Rc * Wd | Tl*Tw*Th | |||||

| LCH2020 | 0.12-1.2 | 0.3 | manual | 1.5 | 3474 | 625 -- 2625 | 775 -- 2775 | 0.84*1.24 | 1454*1100*174 |

| LCH3040 | 1 | motorized | 1.5 | 5908 | 1500 -- 5500 | 950 -- 3950 | 1.71*1.90 | 2144*2000*225 | |

| LCH3550 | 1 | 1.5 | 6408 | 1500 -- 6500 | 950 -- 4450 | 1.71*1.90 | 2144*2000*225 | ||

| LCH4050 | 1 | 1.5 | 6908 | 1500 -- 6500 | 950 -- 4950 | 1.71*1.90 | 2144*2000*225 | ||

| LCH5060 | 1 | 1.5 | 7908 | 1500 -- 7500 | 950 -- 5950 | 1.71*1.90 | 2144*2000*225 | ||

| LCH8060 | 0.9 | 1.5 | 11090 | 1500 -- 7500 | 1330 -- 9330 | 3.00*2.68 | 3034*3270*305 | ||

Column and Boom goods supply range:

a. Frame assembly: column, welding arm, chassis, rotating mechanism, moving mechanism, elevating mechanism, boom expansion mechanism, cross trimming, and ladder.

b. Electrical control system: electrical box, manual control operation box and its accessories

c. Welding system: Zhouxiang MZ-1250 welder (optional), with welding head and wire feeding system, flux recovery system(optional)

d. Spare parts: three 2A melt cores and one piece of documentation

Column and Boom Details:

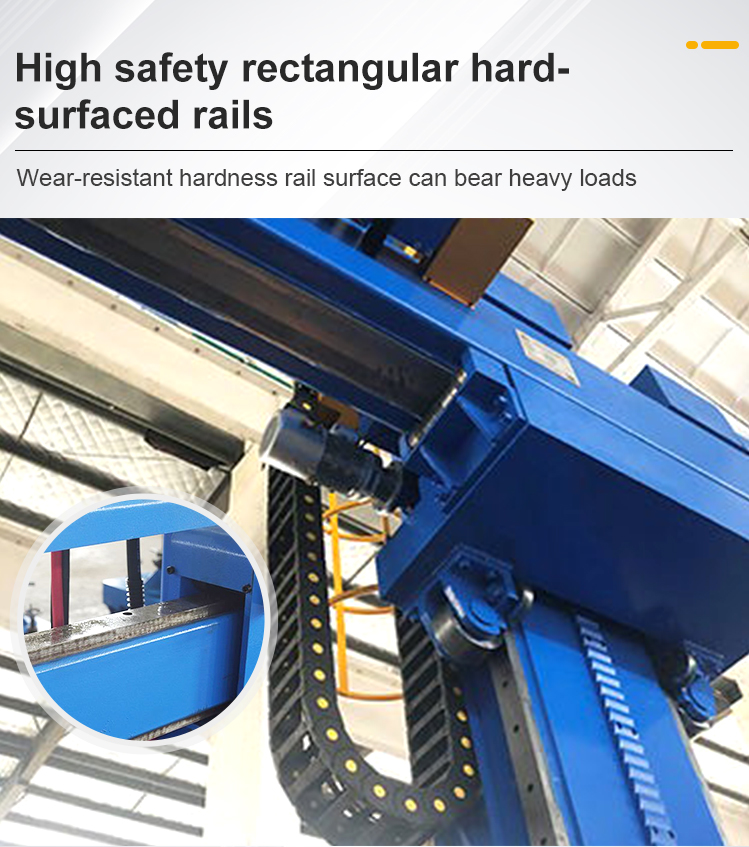

1: Hard-surfaced rails can withstand enormous pressure.The guide rail surface is not deformed, makes the boom move smoothly, ensuring that the equipment still has high precision and safety after long-term use.

2: The swing speed and swing range of the welding oscillator can be adjusted, and it is easy to meet the requirements of different welding seam widths and swing speeds, greatly reducing the labor intensity of the welder and improving the work efficiency.

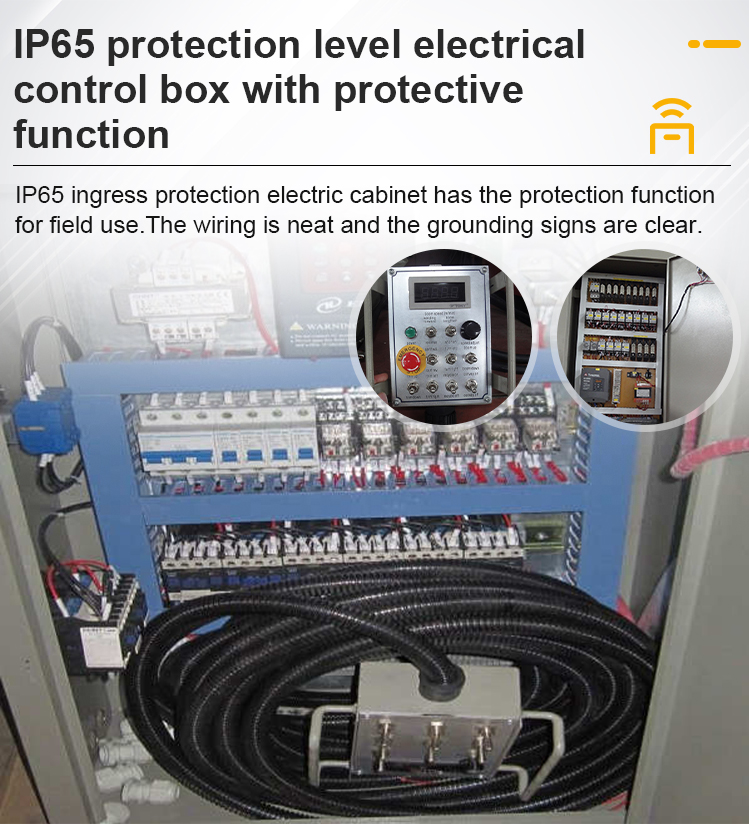

3: Electrical control system adopts IP65 protection against dust and heavy rain and remote wire / wireless control box operation. The high-standard electrical control box has neat wiring and clear grounding signs.

What is “Automatic Welding Center”?

Automatic welding center refers to a key welding process in similar welding components as the core, and the components required to complete the welding process are arranged and combined according to the typical process procedures of the welding process, forming the completion of the welding process. workplace. Welding center is also called welding workstation.

The welding center consists of the following parts:

1. Welding power source: welding machine, machine head, wire feeder;

2. Welding machinery and equipment: such as workpiece roller frame, welding positioner, welding manipulator;

3. Welding auxiliary machinery: such as flux pads, flux conveying and recycling devices;

4. Workpiece transmission device: including feeding, conveying and unloading mechanisms;

5. Automatic welding seam tracking and automatic adjustment device for welding wire dry elongation;

6. Integrated electrical control system.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.