Automatic Horizontal Beam Welding Production Line

$144474-182346 /Set/Sets

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Land,Ocean |

| Port: | Shanghai |

$144474-182346 /Set/Sets

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Land,Ocean |

| Port: | Shanghai |

Model No.: WH0515

Brand: Zhouxiang

Status: New

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Food &Amp; Beverage Shops

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Gearbox, Motor, Pump

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic, Easy To Operate, Energy Saving, Long Service Life

Web Plate Height Of H Beam: 250-1500 mm

Web Plate Thickness Of H Beam: 4-16 mm

Flange Plate Width Of H Beam: 150-500 mm

Flange Plate Thickness Of H Beam: 5-20mm

H Beam Length: 4000-15000mm

Max H Beam Weight: 4000kgs

| Selling Units | : | Set/Sets |

| Package Type | : | Packaging in steel frame,wooden case,export packaging. |

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

H-beam Horizontal Production Line

H-beam Horizontal Production Line General introduction:

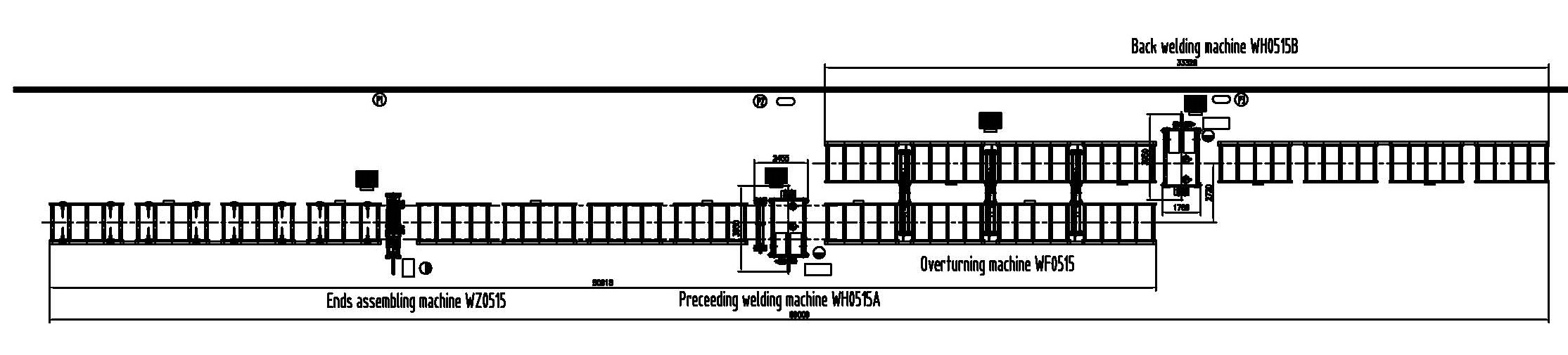

Horizontal type H-beam Production Line is a special welding line for assembling and welding H-beam. Compared with common H-beam vertical production line (first assembling to T type, then welding H-type), it has higher production efficiency and less welding deformation, and is especially suitable for light duty H-beam welding. This production line is composed by assembling machine, preceding welding machine, overturning machine, latter welding machine, and conveyor rollers, which can realize the jobs of H-beam assembling, welding, overturning, and conveying.

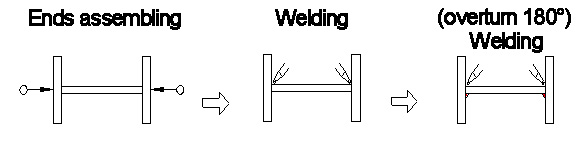

H-beam Horizontal Production Line Technical process drawing:

H-beam Horizontal Production Line Technical parameters:

| Web Plate Height of H beam | 250-1500 mm |

| Web Plate Thickness of H beam | 4-16 mm |

| Flange Plate Width of H beam | 150-500 mm |

| Flange Plate Thickness of H beam | 5-20 mm |

| H-beam Length | 4000-15000 mm |

| Max H beam Weight | 4000 kgs |

H-beam Horizontal Production Line Main technical features:

Traditional H-beam welding line (mainly using vertical assembling and fillet welding in the flat position) has big welding deformation and low production efficiency. It is not suitable for light duty H-beam welding, so we developed this horizontal type H-beam production line, which has following advantages:

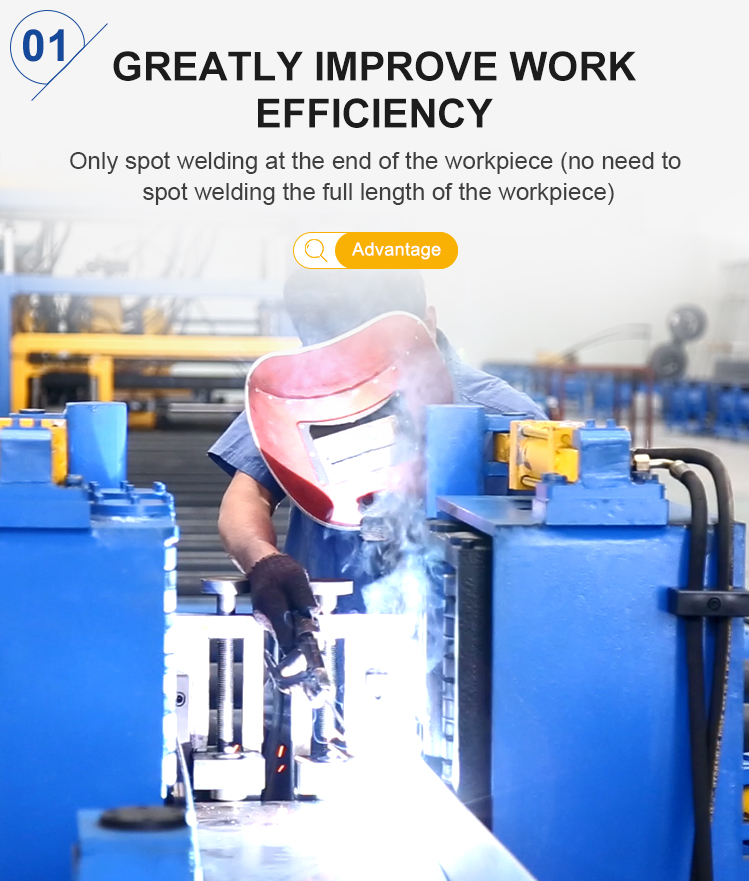

1. When assembly just need spot welding at the end (no need to weld all beam), then come to latter weld process. The machine will position and welding another three free plates, so this will improve the assembly efficiency a lot.

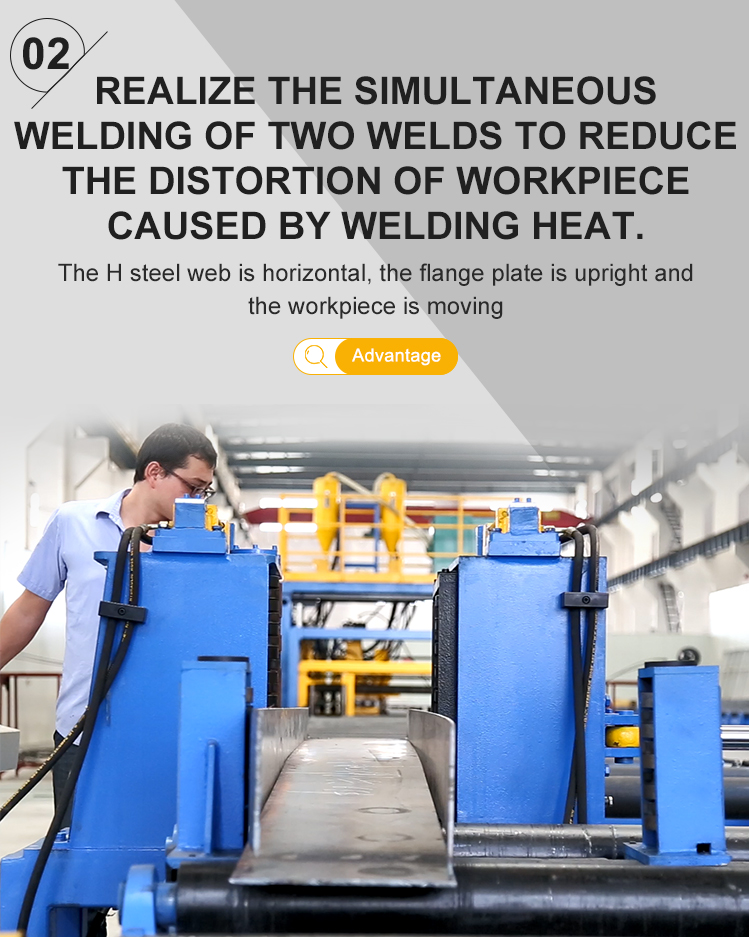

2. The beam put in horizontal position (web plate in horizontal position and flange plate in vertical position), moving the workpiece while welding. This welding way can realized two seams simultaneously welding, which reduced deformation after welding.

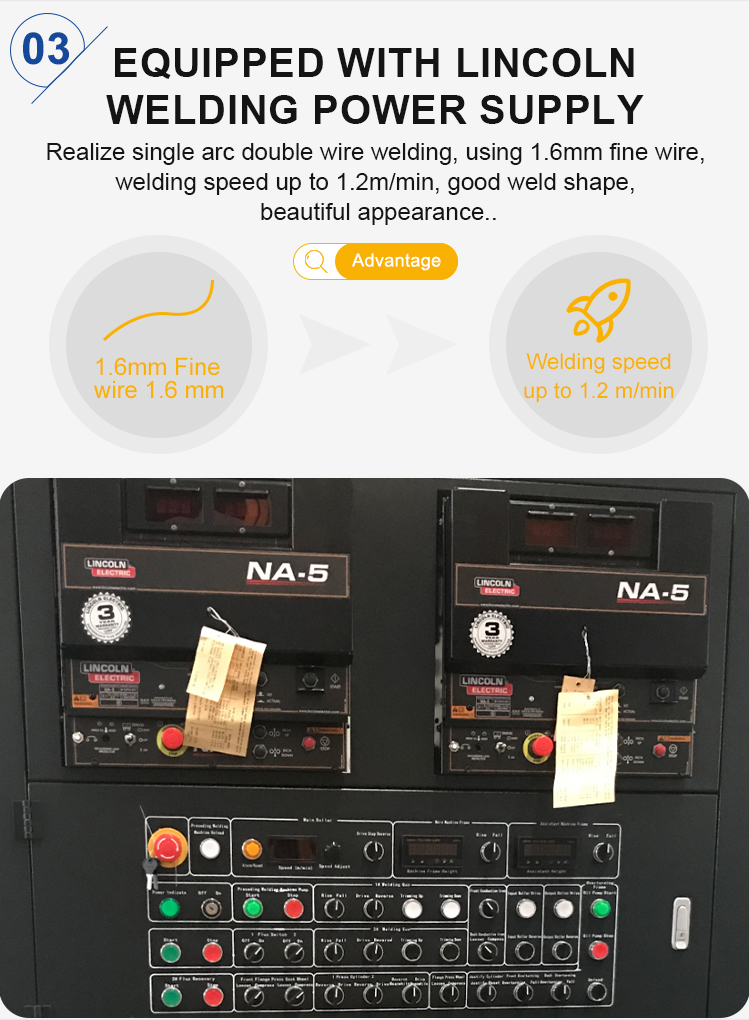

3. The welding power source is American Lincoln DC-1000. It is single arc and double wires .The wire diameter is Φ1.6mm, welding speed is 1.2m/min,so the seam’s quality will be very good and has nice appearance .

4. Compare with traditional line, it has high automation level, so it can reduce working strength, decrease operators .The whole line only needs 4~5 operators.

H-beam Horizontal Production Line Layout drawing:

H-beam Horizontal Production Line Details:

When assembly, just needed to do spot welding of H beam end, after positioned ,then can go into the welding process, welding machine will re-position the three plate, thus increase assemble speed.

The H beam is placed horizontally(web is horizontal and flange is vertical), and the H beam will move during welding, and can weld two seam at the same time to reduce deformation caused by welding heat.

Machine is equipped with Lincoln DC-1000 welding power, which used single arc double wire welding mode, wire diameter is 1.6 mm, and welding speed can reach 1200 mm/min, the welding seams are well formed and look beautiful.

Why choose us--- China Zhouxiang Complete Set of Welding Equipment Co.,Ltd ?

As the largest H-beam manufacturing equipment manufacturer in China, we have strong design and manufacturing capabilities, with an annual production capacity of US$40 million.

How to produce qualified H-beam? It is an important category of our continuous research for 30 years. Our main products are: CNC Control Flame/plasma cutting machine、H beam Assembling machine、H Beam Welding Machine、H beam straightening machine、H beam shot blasting machine、H beam assembly-welding-straightening multi-functions machine、H beam Horizontal Productions Line、automation welding machine etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.